What I saw a man do made me question the professed causes and benefits of the industrial revolution, which is the wholesale replacement of skilled craftsmen with autonomic machines. Many of you are familiar with today’s industrial robots, metalworking machinery, the synthesis of the two, and their inherent precision capabilities. Consider how really specialized those devices are and how limited in what each can produce relative to programming and setup time. Now, consider this:

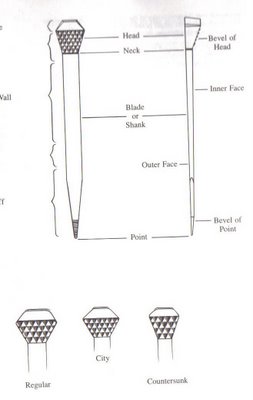

I am a practicianer of the manly arts of Horseshoeing and Blacksmithing, and if you are like I was, you’re pretty sure the old ways of fashioning metal are fairly crude and imprecise. One of the tasks I was given to perform at horseshoeing school was to fashion a punch that would impress the exact precise shape of a certain type (there are many) of horseshoe nail head into an piece of red hot steel. I chose to make an “E” head punch for a #5 nail. An “E” head nail has roughly the shape listed as ‘countersunk’.

I took measurements of angles, dimensions, used a caliper to measure the cross section of the shank, drew it up and roughed it out with hammer, fire, and anvil, then went to the grinder with my drawings and calipers and protractor to finish it up. Two hours later I was not satisfied. Disgusted, I went to the head instructor and proprietor of the school and expressed my frustration.

“Let me see that.”

I presented my work. He glanced at my handful of tools and drawings, smirked, arose from his desk and without a word went to the workshop to my anvil, started the forge and placed my work into it.

“What’s this supposed to be?”

I replied, “‘E’ five.”

“OK. Watch.”

He opened the forge door and removed the glowing steel. Placing it on the anvil at an angle, he spat into his palm, hefted my hammer and obliterated what I had so painstakingly wrought in three “Thor”-like blows. I stood in shock! Two hours of work gone, and this ham handed SOB squashed it in three blows and 5 seconds. Then…

He rotated the piece, so… WHAM! (full on hammer-stroke brought from above his head).. WHAM!WHAM!. Rotated it again, WHAM!.. WHAM!WHAM! …. eyballed it WHAM! fliped it over, spat. tap-tap-tap..tap, eyballed it rotated itWHAM!…. WHAM!

“See?”

And he departed the workshop. Total working time elapsed – less than 15 seconds.

I thought ‘Bullshit!’ and got out my measuring instruments. No bullshit. I tried the punch on a piece of steel and dropped a #5 E-head into it resulting cavity. It was perfect.

P E R F E C T

Not close, not good enough. Perfect. As if you had used the nail itself to make a mold into playdoh and dropped the nail back into it.

“How can he do that?,” you ask.

Answer – Because he is a master and student of an old-world craft, and most importantly, because nobody ever told him he couldn’t. He has no formal education in modern methods of machining and is largely ignorant of any precision machinery beyond a common drill press.

Nice.

I have a BS (yeah, it could mean that) in Computer Science and a minor in Mathematics. On this blog I first learned about the Youtube channel for Essential Craftsman. The amount of math that this craftsman can do in his head or using a speed square puts most of my colleagues to shame.

I spent most of my life believing that the things I learned in books made me smart. In the past few years I’ve learned to respect what can only be learned, and deeply known, by constant work and effort.

Thanks for your blog.

Train mind, body, and eye together. Read a first hand account of an early Arctic exploration. Ship’s carpenters used to not measure anything.

Captain: “Build me this; yay long, yay tall, and yay wide” and the carpenter would ponder, then commence to cutting.